Toyota Prado 150 Series PDI Heavy Duty Transmission Cooler suit 5 speed A750 and 6 speed AC60

Toyota Prado 150 Series PDI Heavy Duty Transmission Cooler suit 5 speed A750 and 6 speed AC60

In stock and ready to send out.

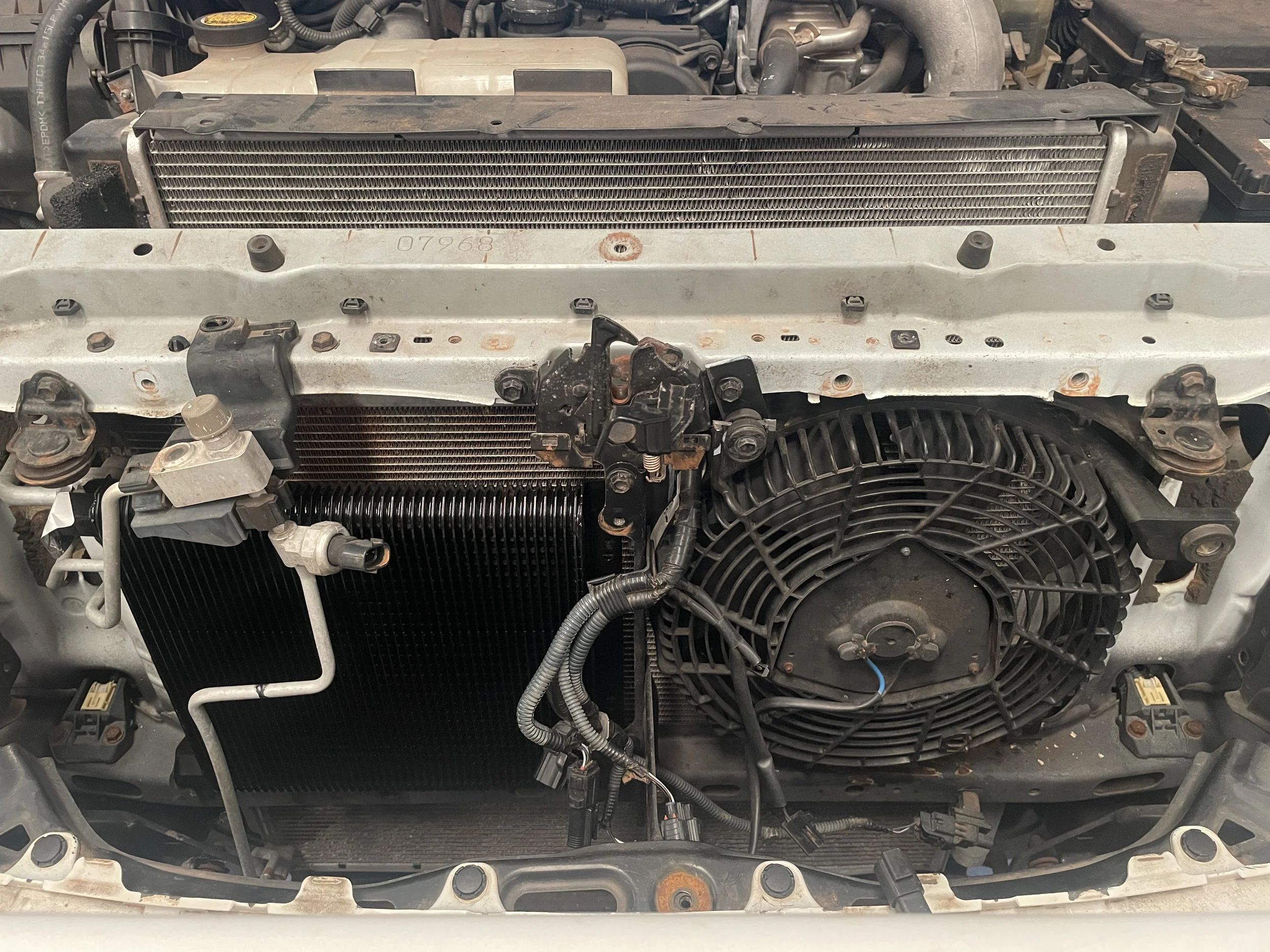

Specific for the KDJ150 series Prado we have chosen to move the thermo fan to the other side of the engine bay. This adds an extra task to the install, but the position is ideal for the engine power delivery as it sits in front of the intercooler and makes the transmission hose plumbing short and tidy.

For GDJ150 Prado, the port on the condenser, makes moving the fan to the passenger side very difficult, due to space limitations and would require the installation of a aftermarket fan.

NOTE: A number of other aftermarket systems place their transmission cooler in front of the cold side of the intercooler. We have had a number of retired mechanics realise the effects of this and looking to upgrade their intercooler since the higher intake air temps result in less torque and the transmission come out of lockup, which makes even more heat - they ended up with both intercooler and transmission cooler from PDI.

By default, all PDI external transmission coolers are designed to be market leading through:

· Maximum efficiency 29,000BTU (energy dissipation unit of measure).

- Stacked Plate coolers - this is the best design you can use.

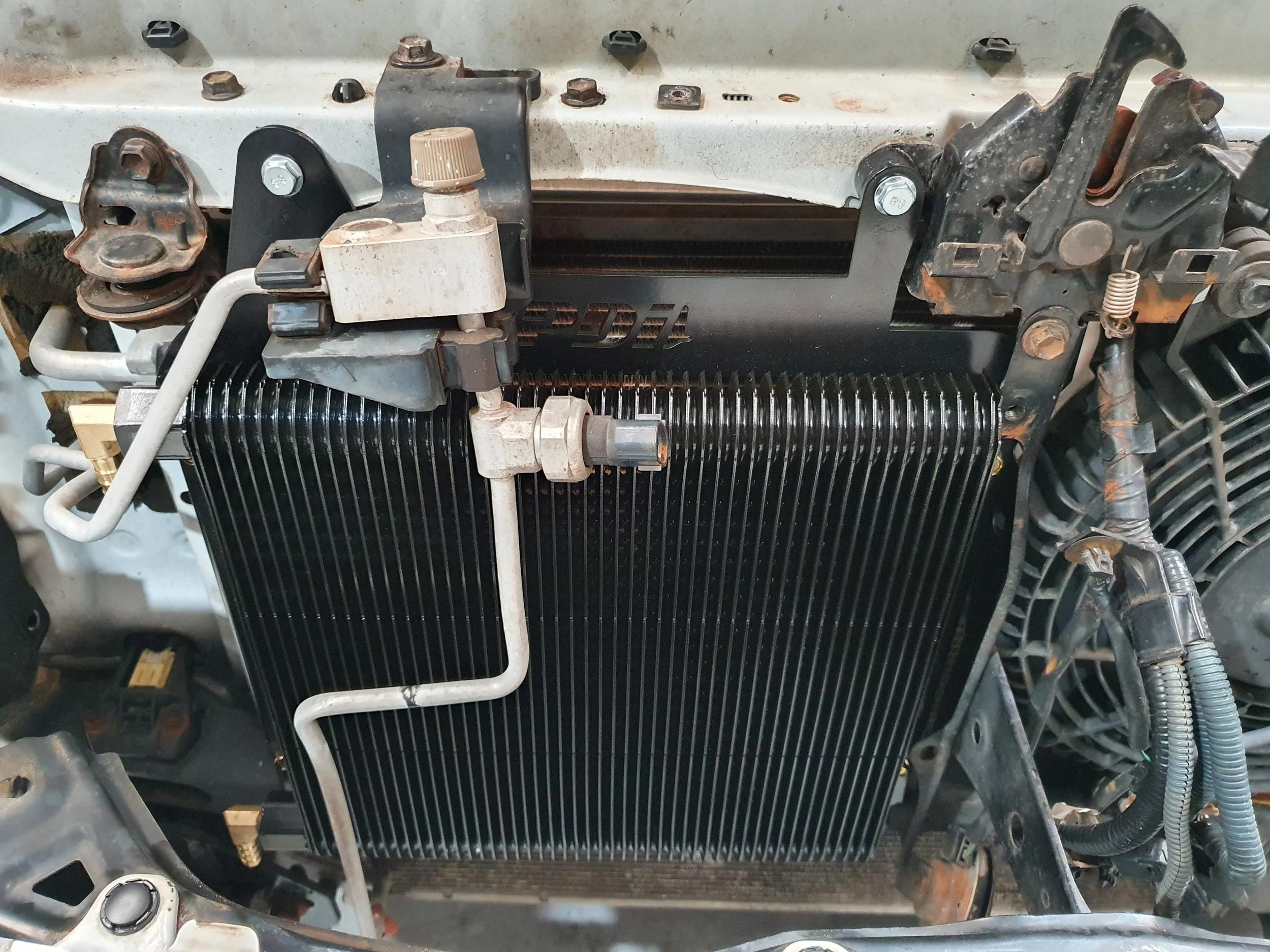

· Steel one-piece brackets (zinc plated and coated) to eliminate flexing of the aluminium cooler.

· High quality transmission cooler hose (rated to 400psi).

· Outlets on the side to prevent air locks inside the transmission cooler.

NOTE: Having the outlets at the bottom make the installation easier as the pipes are run down under the radiator, but if you get an airlock (from initial installation empty) there is a strong chance you will never actually fill the top of the coolers with fluid and designed cooler efficiency may never be reached.

Suitable for the following engines: 1GD-FTV 2.8L Diesel, 1KD-FTV 3.0L Diesel and 1GR-FE 4.0L Petrol

Additional införmation below

PLUS: PDI have developed an upgraded front mounted intercooler kit for the 150 Prado that will allow the engine to maintain its higher torque and power output under load. This means your gearbox is more likely to remain locked up while pulling up long hills and therefore significantly reduce transmission temperatures. For more info CLICK HERE

Is an aftermarket transmission cooler required?

New car manufactures make a car to a price and ensure it meets the expectations of most customers. If you aren’t towing are are running standard power then, quite rightly, you probably won’t be thinking of adding a transmission cooler. If you want to be more scientific, then measure the transmission temperature and decide if you are comfortable with the temperatures you are seeing. If you will be towing a caravan or camper trailer then it is sensible to install an external transmission cooler, to make the transmission last as long as possible by keeping the temperatures down.

The ideal operating temperature for automatic transmission fluid is somewhere between 80 and 110 degrees C. Here’s what can happen above this range:

At approximately 115 degrees C, important additives begin to cook in the automatic transmission fluid (ATF). The result is the formation of varnish inside the transmission.

At approximately 125 degrees C, internal transmission seals, which are often manufactured from a polyacrylate material, begin to harden. The end results are internal and external leaks as the the seals lose their elasticity.

At approximately 145 degrees C, transmission clutch plates begin to slip because the oil is breaking down further.

At approximately 160 degrees C, seals and clutches effectively burn out. Carbon forms in the oil and your effectively killed the transmission. Often, a transmission will die within a few thousand km after experiencing 150-plus degree heat.

It is worth noting that the AT temp warning light on a 4 speed auto Landcruiser came on at 150degC and that generally means you are well beyond a safe temperature.

When adding an aftermarket transmission cooler, can you go too big?

In Australia with our high temps and the area available to mount transmission coolers the answer is no. The only reason for running a smaller unit is cost and this will mean a lesser capable unit.

Single piece steel brackets.

We use 3mm mild steel brackets which have been zinc plated and coated. Using one piece bracket to hold the cooler means flexing of the cooler is kept to a minimum and and body flex or vibration are much less likely to hurt it.

Stainless brackets look smart and don’t need a coating, but stainless steel will cause an anodic/cathode reaction resulting in corrosion in the cars body around where it is mounted since the exposed metal allows electron transfer, which is the start of the process.

Stacked Plate or Plate and Fin?

The market doesn’t seem to have tube and fin units, which were cheap (easy to make) and are the most inferior design. The next step up in efficiency and still cost effective are the “plate and fin” design. These seem to be the most commonly available units and come in a few different sizes. Dual setup versions of these are available to increase efficiency and the fluid has to run through both units. This means extra connections, double the restriction to flow and the resulting overall efficiency not equivalent to double the single unit.

Stacked plate design is the optimal setup being the most efficient and durable construction. The internal restriction to flow is minimal, which is important as there is lots of flow through these units and restricting flow may affect the life of the transmission.

Tube and fin, is a light weight intercooler design system suited to air to air intercooler systems, although all PDI intercoolers use a “bar and plate” design. We have seen the full aluminium tube and fin system used on transmission cooler designs, but haven’t seen it to be very effective. We have aligned ourselves with one of the best transmission cooler specialists and manufacturer on the market with our range to provide a quality kit.

In front of the intercooler or behind?

The intercooler has the potential to extract lots of heat. For example, the highly efficient PDI intercooler fitted to a Landcruiser 100 series when towing a heavy camper trailer at 100kph is able to drop the intake air temperatures down from 150-160deg to 40deg on a 25deg day. The heat removal can be much high when pushing hard along a beach. With this heat loading in front of a transmission cooler it can be hard to drop transmission temperatures when it is most required.

Transmission coolers aren’t always working - when the torque converter is “locked up” the transmission isn’t making anywhere near the heat it can do when the torque converter is working. Normally for highway driving the torque converter is locked up so there is no extra load being placed in front of the intercooler in this situation, however on the beach with the torque converter unlocked we want to give the transmission the best chance to not get too hot so prioritise transmission cooling.

We also don’t see the point in hiding the cooler behind the lower bumper where air flow is limited and we can’t be expected to see much heat extraction.

Why have we chosen to position the transmission on the drivers side?

As our primary business is intercoolers and we pride ourselves in designing and producing the largest and best performing units on the market we have a keen interest in performance and maximum efficiency when under load. For most driving the intercooler does a lot of its work in the side closest to the turbo and the other half continues to do its job. If the transmission cooler is placed on the intake (normally passenger) side of the vehicle then it can put heat back into the intake air.

in the 150 series Prado we have chosen to move the thermo fan to the other side of the engine bay. This adds an extra task to the install, but the position is ideal for the engine power delivery and makes the transmission hose plumbing short and tidy.