PDI 6 speed (6R80) Auto Conversion Kit for Landcruiser 80/100/105 and HDJ79

PDI 6 speed (6R80) Auto Conversion Kit for Landcruiser 80/100/105 and HDJ79

The 6R80 into Landcruiser development began in late 2021 by PDI as we needed a gearbox that could meet the requirements for customers exceeding 400hp at the wheels. Our own manual FTE converted 105 was pushing 302kW at the wheels and we knew the box was only just able to keep itself together. Our first install was completed in march 2022 with upgraded internals and torque converter – it has been going well since then with 280kW at the wheels and has been used for off-roading, cruising, daily driving and towing the family 23ft caravan.

We have adapters for the 1HD and 1FZ engines.

To place an order please contact us directly since we need to determine shipping options as this will need to be sent out on a pallet.

Why go auto?

Easy without the hassle of changing gears

When off-roading - autos are easier and more tractable under all conditions.

Modern autos are faster when coupled to the same engine. The 6R80 does a better job at power transfer than the 100 series Land Cruiser range.

Easier for towing.

Shifting points can be changed using downloadable software to make it change gears when you want.

In Landcruiser’s, we want to know the gearbox can handle the power. The Toyota 4 and 5 speed are not strong enough for those who want to get some significant upgrades. The manual starts breaking around 400hp, clutches are expensive and don’t always handle the torque either.

What are the considerations when going with a different manufacturer transmission?

Externally - they offer for 4WD or 2WD drive (so rear outputs are different and bolt options for adapters) and many different engines so the bolt pattern on the bellhousing will be engine specific.

Internally – depending on the engine they will be designed to have a rated torque figure. Fortunately we can tell what that is by the name of the box. The first letter indicates the amount of gears and the number after the letter is its torque rating (unmodified).

4L80 – 4 gears, factory rated for 800nm max input torque

6R80 – 6 gears, factory rated for 800nm max input torque

8HP50 – 8 gears, factory rated for 500nm max input torque

8HP70 - 8 gears, factory rated for 700nm max input torque

8HP95 - 8 gears, factory rated for 950-1000nm max input torque (as found in the Hemi Hellcat engine).

As you can see boxes like the 6HP and 8HP have many different specifications like the 8HP45 in a 3 series BMW. Increases in torque and power handling can be achieved with line pressure increases and after that internals need to be swapped out.

What is the 6R80?

The US-produced Ford 6R80 transmission is based on the robust ZF 6HP26 design, which was used by automakers world-wide for over 14 years. Enhancements were added by Ford to further improve the transmission, including the addition of a ratchet-style low one-way clutch, and removal of the internal TCU for the 2011 model year, easily enabling stand-alone control. The 6R80 has already been field-proven to accept up to 1000HP in stock form, with only ECU tuning. With aftermarket components, the 6R80 has been proven to handle much more power.

Why we like the 6R80?

PDI have chosen to go with the F150 6R80 box, with the Coyote bellhousing pattern due to the larger torque converter and neater installation, which allows for a relatively narrow adapter to the engine. This is known to be a reliable box in the USA where it was fitted to the F150, Expedition and Ford Mustang. In Australia is was released in the Ford Ranger and Everest. Ford Australia chose to couple it with an inferior torque converter, resulting in gearbox failure and therefore many auto transmission shops are aware of these boxes. Performance shops in Australia focusing on the XR6 turbo Barra engines know the 6HP26 can handle a hiding but if you want to make it stronger then going into the 6R80 parts bin is a good idea.

The F150 gearbox also comes with a solid torque converter. Stock converters already employ a multi-plate torque converter clutch, enabling greater power handling in lockup. We have had the internal bushing replaced with a bearing for our boxes while the converter is being inspected.

How do we control it?

US-Shift supply the standalone controllers for these boxes and have a series of patents on how it works. If its not changing nicely, you can clear the shift learning and it will reconfigure itself after driving around for a while. This can compensate for clutch wear and actuator variation over time.

We are waiting on a remote screen to be release for the controller, which means the main unit will be able to go under the panel. The controller suppler says that existing units will be able to be returned and upgraded in the next few months.

The unit has a digital speedo output that can be fed into the speedo for those also changing diff ratios and tyre sizes.

What inputs are needed to make it work?

We need a TPS (throttle position) input and RPM plus power feeds and then need to connect a starter motor relay for Park and Neutral starting only. This means the HDJ100 factory (non cable) cruise control won’t work. On a FTE converted 105 the FZJ105 cruise control (cable) system has been made to pull on the pedal itself and therefore works normally. If you have a mechanical system like the 1HDFT engine then you will need the TPS mounted on the injection pump.

What can it handle?

From information out of the USA, we are confident the standard box will suitable for 300hp/240kW at the wheels and 850nm. It may be

What about the 400hp option?

This is a well-trod path in the USA for the fast Mustangs etc that are punching out over 1000hp and parts are readily available in Australia. Since in the diesels we need to think about torque, we would use the same considerations for a 400-450hp diesel build. This would be stage2 clutches, billet internals for some components.

Excedy stage 2 clutches offer a 40% increase in clutch surface area – these will be impossible to slip with correct line pressure.

Upgraded intermediate shaft.

Upgraded planetary set.

Triple plate torque converters – these can be locally built or ordered out of the USA. These are stronger, but can be a bit rattly. Time will tell if these need to be considered.

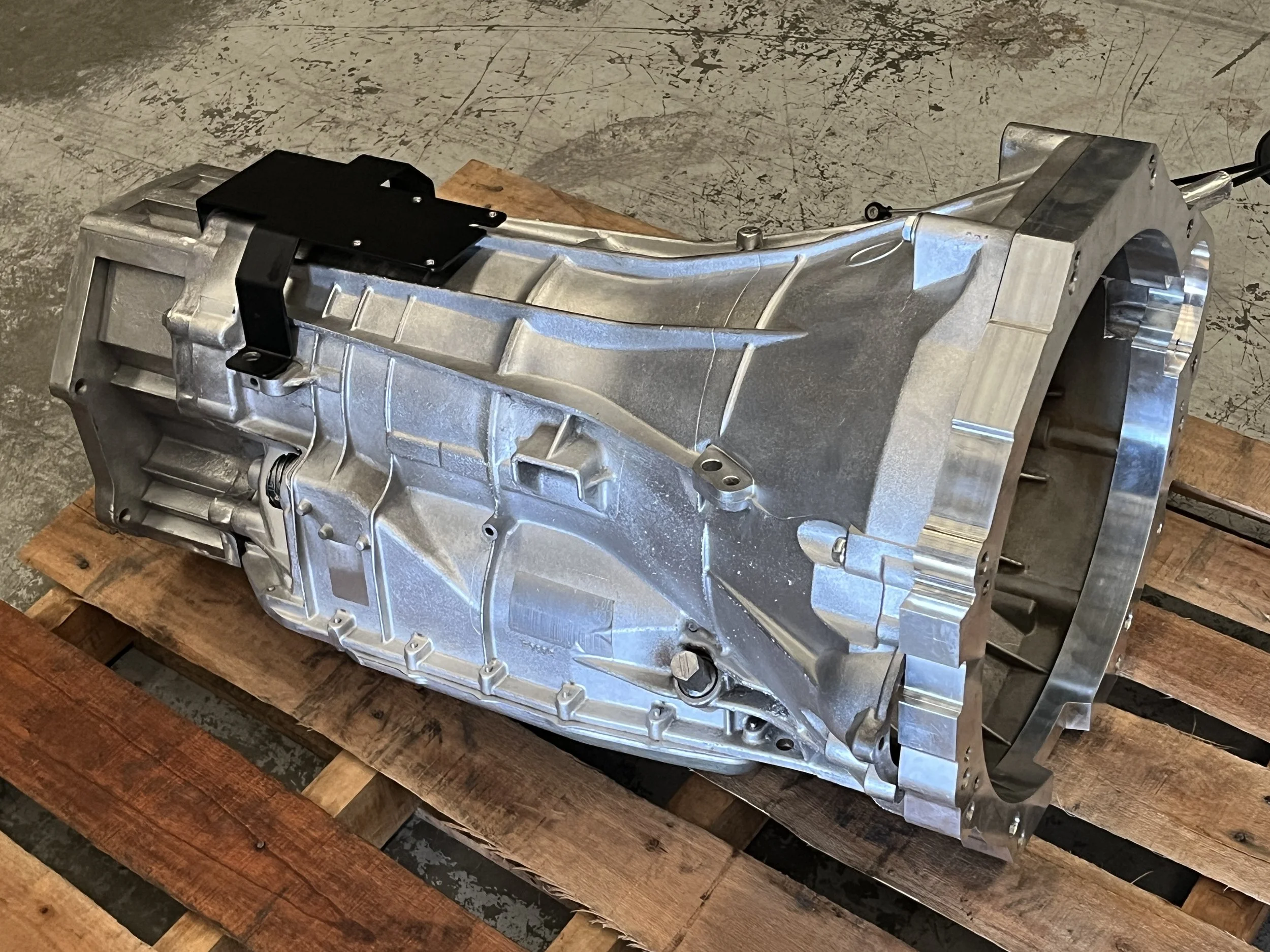

What comes with our standard kit?

Inspected, but second hand 6R80 gearbox from F150.

Inspected and updated torque converter

Stand-alone gearbox controller, lots of neat functions and clever shift learning function.

Engine to gearbox adapter with bolts

Torque converter adapter – incorporated in torque converter for our first release.

Transfer case adapter.

Spline adapter from gearbox into transfer case

Shifter (with Tiptronic movement) and cable to suit transmission.

Floor plate adapter to suit auto 100 and 105 series Landcruiser

What else is needed?

Tail-shaft lengths will need to be adjusted. We figure it will be more cost effective to have your own shaft lengths adjusted than supplying new (and then modified) units.

Engine is to be fitted with original auto sandwich plate, flex plate and balancer. Bolts that go through flex plate into torque converter are also required.

We have floor plates designed for the 100/105 auto (4 or 5 speed floor plan). If changing from a manual you will need to reconfigure the position of the transfer case lever onto the gearbox and this may require a longer shaft.

This is designed to use the gearbox crossmember in the auto location. This is 80mm further back than the manual location. If installing into a manual body, modified crossmember is the best way to deal with this, due to inner support brackets welded to the chassis and threads installed inside chassis for manual or auto.